Gap Bed Centre Lathes

Semco has been successfully supplying our cost-effective range of gap bed centre lathes for many years, with quality and reliability as key priorities. Our lineup covers everything from compact models for students and educational use, to heavy-duty machines with up to 2,200 mm swing and 15,000 mm between centres—we cover it all. Many models are in stock and ready for quick delivery, so give us a call to discuss your needs.

All machines are CE and CA marked.

Standard features include

All machines have 3 & 4 jaw chucks, steady rests fixed and traveling. Also included are 2 axis DRO systems, tools, fixed centres and full flood coolant system.

Options

These machines can have extra chucks like 2 or 6 jaws with special options like self centre or independent jaws.

Specifications

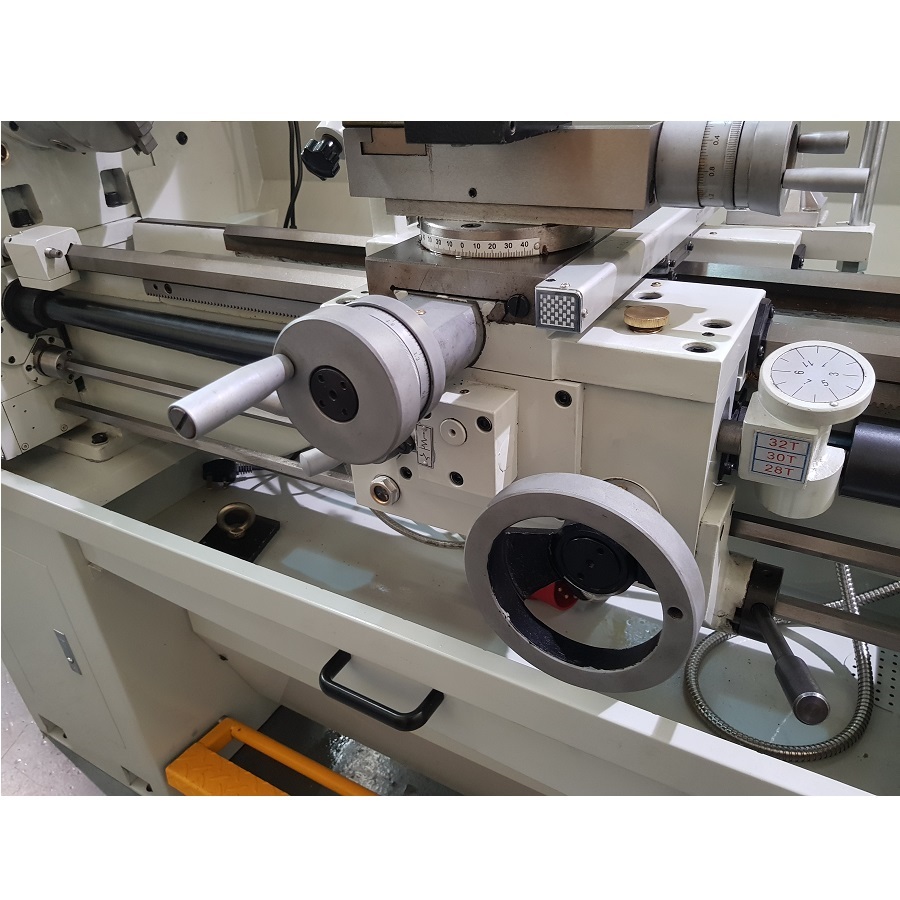

Gap Bed Centre Lathes Gallery

Lathes have long been essential tools for producing round components such as shafts, axles, worms, and wheels. Even today, manual lathes are widely used for one-off part production and the repair of worn components. Their enduring versatility means we continue to offer a wide range of accessories, including various types of chucks, fixed and traveling steadies, taper turning attachments, tool holders, boring bars, and more.

All of our manual lathes come equipped with both 3-jaw and 4-jaw chucks, as well as fixed and traveling steadies as standard. Our smallest gap bed centre lathe, the L320, is ideal for students or workshops where space and budget are limited. It comes fully equipped and ready for use in any workshop or training environment.

At Semco, we can also build special-purpose lathes tailored to your application, with options such as tool post grinders or custom chucks.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.