Slant Bed CNC Lathes

Slant Bed CNC Lathes

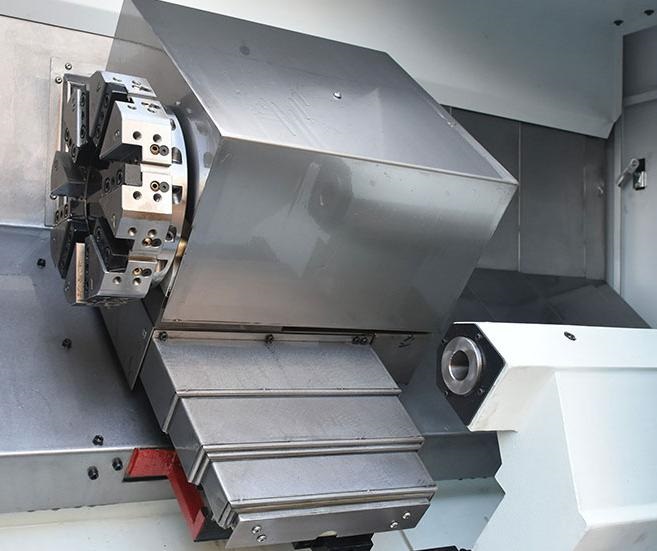

Semco has refreshed its lineup of slant bed CNC lathes, delivering a cost-effective solution to meet modern manufacturing demands. Designed with a heavy-duty cast construction set at a 45-degree angle, these machines offer outstanding cutting efficiency, rigidity, and stability.

Each model comes equipped with power chucks and tailstocks as standard, and you can choose between Fanuc or Siemens controls to match your preference or production environment.

Get in touch today to speak with one of our experienced engineers and find the right machine for your application.

.

Available with Siemens or Fanuc control options. CE & CA Marked.

Specifications

Axis Drives

Precision Motion and Drive System

All axes are driven by direct-drive AC servo motors from Fanuc or Siemens, paired with C3 high-precision TBI ball screws for exceptional accuracy and responsiveness. The machine’s slides run on HiWin linear guideways, ensuring smooth, stable, and highly precise movement throughout all operations.

Smart Design for Enhanced Performance

The slant bed lathe was developed to minimize swarf build-up by allowing debris to fall away from the cutting area, reducing the risk of marks or damage to finished components. This design also enables parts to either drop off cleanly or be collected using a parts catcher, streamlining the production process.

In addition, the slanted structure supports heavier and more rigid bed designs, significantly improving tool life through enhanced stability and vibration control. To further boost performance, linear guideways can be integrated behind the sliding guards, increasing machining speed and improving surface finish quality.

.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.